TRUSS DECK

ADVANCED MACHINE

Our company has introduced the totally automatic production line that adopts 6.85-meter-long overall rack and makes adjustment as a whole through electric to meet the welding needs of the steel truss deck of different height.

HIGH EFFICIENCY

The steel bar truss deck is a new metal deck design and it is widely applied for the mezzanine construction of commercial and civilian buildings, such as factories, hospitals, gymnasiums, schools, bridge projects and residential buildings. The steel bar truss deck is composed of two parts, the steel bar truss deck melted onto the galvanized steel sheet.

Advantage

.

.

Technical parameters

| Name | Specification |

| Zinc Coating | 80GSM - 275GSM |

| Steel Sheet Material | 240MPa - 345MPa |

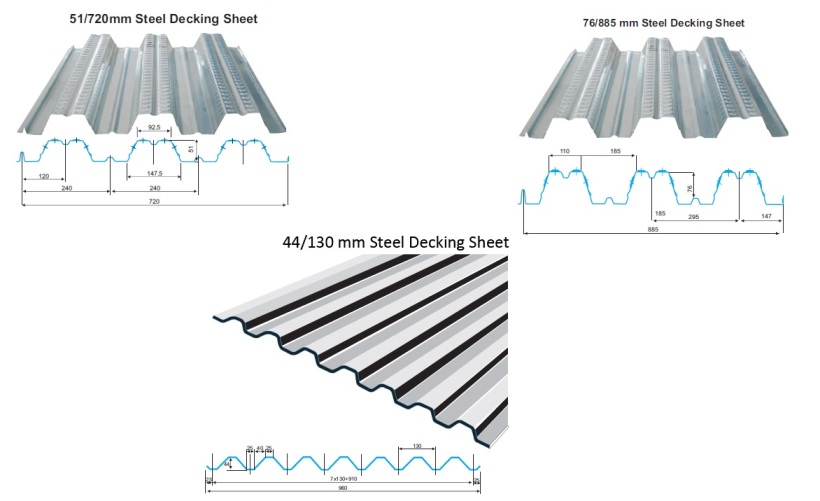

| Crest Height & Width | 51/720mm, 76/885mm & 44/960mm |

| Steel Sheet Thickness | 0.8mm, 1.0mm or 1.2mm |

| Length | Customized as per customer requirements |

| Standard | As per IS:513, IS:277, IS:14246, and AS:1397-G300-Z275 |

Manufacturing technology

The steel truss deck can significantly reduce 60%-70% re-bar binding engineering on site, which shortens the construction period, guarantees construction safety and is in line with national energy conservation and environmental protection requirements.

Installation

1. Lifting

2. Edges and angles

3. Laying

4. Vertical bearing steel welding

5. Stud welding

6. Edge template welding

7. Site layout pipeline

8. Additional reinforcement, field installation

9. Concrete pouring

10. Finished product protection

FAQ

What is the diameter of the rebar?

Is your company responsible for the construction of the site?

What is the application of the steel truss deck?

Whether can the order be delivered on time?

Do you provide free samples?